New Heritage Windows With Superior Polyamide Thermal Break

Home > New Heritage Windows With Superior Polyamide Thermal Break

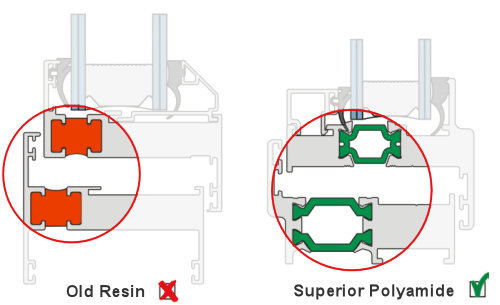

What's The Difference Between Polyamide & Resin Break Barrier

Inferior Resin Break

A resin Break between inside and outside profiles provides poor thermal efficiency. Externally glazed. (left)

Approximate U-value of 2.2 W/M²K.

Superior Polyamide Break Barrier

In comparison the wider new Polyamide break barrier, is a thermally efficient and up to date window conforming to current and proposed requirements of Part L of the Building Regulations. Vents are now internally glazed for added security, and ease of installation. (right)

U-Value of 1.95 W/M²K

Our Heritage Windows have been designed with the future in mind. All of our aluminium window and door systems have long since been upgraded to a superior polyamide thermally break barrier as opposed to the old resin thermal break barrier. This old resin system is being phased out, but is still in use by some window suppliers. Polyamide gives at least a 30% improvement to all thermal efficiency and Uw figures on a typical window (1480 x 1230mm) when compared to the old redundant resin break.

Advantages Of Polyamide Thermal Break Over Resin Thermal Break

- Meets the building regulations for NEW BUILD jobs ( now and in october 2010 when more stringent regulations come into force).

- Polyamide has a much improved thermal performance i.e. at least a 30% improvement in Uw figures on a typical window (1480 x 1230mm).

- Ability to have larger thermal barrier i.e. Polyamide strips of up to 30mm compared with 5/6mm PU resin thermal break.

- Dual colour options far easier and cheaper to achieve with polyamide i.e. individual sections can be painted before assembly.

- Increased flexibility (Hybrid Sections) - using Premium window sections can be used in a number of combinations.

- Polyamide has similar mechanical properties to aluminium i.e. assembled profiles retain their rigidity and have far greater strength.

- Has the same heat coefficient as aluminium (melting point, etc.) so it does not crack or distort when subject to extreme cold or heat.

- Resin gives off poisonous gases when it melts or ignites in the event of a fire.

- Polyamide is a fiberglass compound which means that it can bend without cracking, and can easily produce curved and arched windows. (Resin becomes weakened and tends to splinter under the tensile strain)

- Much reduced risk of condensation / fogged up sealed units.

Other Information

Contact Information

- We are based on

- Canvey Island,

- in Essex,

- Get An Address »

- T: 01268 681612 (Office)

- T: 01268 695100 (Showrooms)

- F: 01268 510058 (Office)

- E: sales@duration.co.uk

©2026 Duration Windows. We reserve the right to change specifications.

We continuously wish to improve and we kindly inform you that all incoming and outgoing phone calls may be recorded for quality and training purposes.